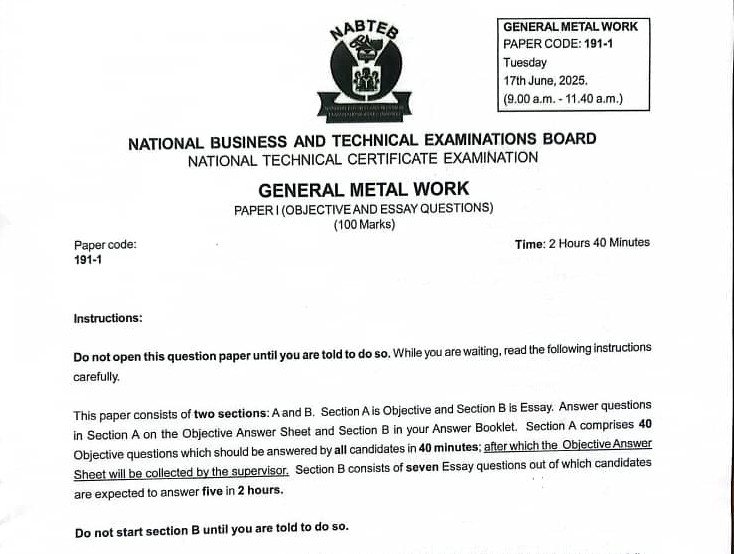

METAL WORKS OBJ

01-10: BADBDCDBBA

11-20: CBCDABABDC

21-30: ACAABBBADA

31-40: BCABACCCCA

COMPLETED

NABTEB GENERAL METAL WORK ANSWERS

INSTRUCTIONS: ANSWER FIVE QUESTIONS ONLY

(1a)

(i) Sterile gauze pads

(ii) Adhesive bandages

(iii) Antiseptic solution

(iv) Scissors

(v) Cotton wool

(1b)

(i) Always wear personal protective equipment such as safety goggles, gloves, and boots to prevent injuries.

(ii) Keep the workshop clean and free from oil spills or sharp objects to avoid accidents.

(iii) Do not use any machine or tool unless you have been properly trained to handle it.

(iv) Turn off all electrical machines and unplug them when not in use to prevent electric shock or fire.

(v) Store all tools and materials properly after use to maintain order and prevent accidents.

(2a)

(i) Presence of Iron: Ferrous metals contain iron as their main element, which makes them magnetic and prone to rust. Non-ferrous metals do not contain iron, so they are usually non-magnetic and resistant to corrosion.

(ii) Weight and Strength: Ferrous metals are generally heavier and stronger, making them suitable for construction and industrial purposes. Non-ferrous metals are lighter and more malleable, making them ideal for applications where weight and flexibility are important, like in electrical wiring and aircraft parts.

(2b)

(i) Ferrous metals: Cast iron, Mild steel

(ii) Non-ferrous metals: Aluminium, Copper.

(3a)

(Draw the diagram)

[img]https://i.ibb.co/8nLBQq3r/oxy-acetylene-welding.jpg[/img]

(3b)

(i) Improved Efficiency: High-pressure systems increase the rate of energy transfer, making machines and processes more efficient.

(ii) Smaller Equipment Size: High pressure allows the use of smaller pipes and components while maintaining the same output, which saves space and materials.

(iii) Faster Operation: Systems running under high pressure work faster, especially in hydraulic and pneumatic operations, leading to increased productivity.

(iv) Better Performance: High pressure provides greater force, which is useful in cutting, pressing, and other mechanical tasks that require strong output.

(4a)

Heat treatment is a process of heating and cooling metals in a controlled way to change their physical and mechanical properties without altering their shape.

(4b)

(i) Annealing

(ii) Hardening

(iii) Tempering

(4c)

(i) Annealing: This involves heating the metal to a specific temperature and then slowly cooling it, usually in a furnace. It softens the metal, makes it easier to work with, and improves its ductility and machinability.

(ii) Hardening: This process involves heating the metal to a high temperature and then rapidly cooling it, usually in water or oil. It increases the hardness and strength of the metal, making it more wear-resistant.

NABTEB GENERAL METAL WORK ANSWERS

INSTRUCTIONS: ANSWER FIVE QUESTIONS ONLY

(5a)

Upsetting is a forging process in which the length of a metal workpiece is shortened while its cross-sectional area is increased by applying compressive force, usually through hammering or pressing.

(5b)

(i) Anvil

(ii) Hammer

(iii) Tongs

(iv) Swage block

(5c)

(i) Anvil: The anvil is a heavy iron block with a flat surface used as a working base where metal is placed and shaped during forging operations. It often has a horn and holes for bending and forming.

(ii) Hammer: The hammer is used to deliver controlled blows to the heated metal to shape or deform it. There are different types like ball-peen or sledgehammers depending on the task.

(5d)

(Draw the diagram)

[img]https://i.ibb.co/8Zgn6L1/forging-tools.jpg[/img]

RELATED POSTS:

NABTEB General Metal Work 2025 Questions And Answers

NABTEB Animal Science 2025 Questions And Answers

NABTEB Computer Craft Studies 2025 Questions And Answers

NABTEB Physics 2025 Questions And Answers

NABTEB Economics 2025 Questions And Answers

NABTEB Economics 2025 Questions And Answers

NABTEB Government 2025 Questions And Answers

NABTEB Chemistry 2025 Questions And Answers

===========================

(6a)

(i) Steel Rule: Used for measuring straight lengths and drawing straight lines accurately.

(ii) Caliper: Used for measuring the internal and external dimensions of an object with better accuracy than a ruler.

(iii) Micrometer Screw Gauge: Used for measuring very small dimensions such as the thickness of a wire or metal sheet with high precision.

(iv) Tape Measure: Used for measuring longer distances or lengths, especially in construction and carpentry work.

(6b)

(Draw the diagram)

[img]https://i.ibb.co/8Drcr9GD/micrometer.jpg[/img]

===========================

(7a)

(i) Hand drill

(ii) Breast drill

(iii) Bench drill

(iv) Pillar drill

(7b)

(i) Drilling holes in wood: A drill bit is commonly used to create precise holes in wooden materials for screws, bolts, or fittings during carpentry and furniture making.

(ii) Drilling holes in metal: Drill bits designed for metal can pierce through sheets, rods, or blocks of metal, often used in fabrication or engineering works.

(iii) Drilling holes in plastic: Special drill bits can be used to bore clean holes into plastic materials without cracking or damaging them.

(iv) Making pilot holes: Drill bits are used to make small pilot holes that guide screws, helping prevent materials from splitting and ensuring screws go in straight.

(v) Countersinking: Some drill bits are designed to create a conical hole so that screw heads can sit flush with or below the surface of a material, especially in woodworking or metalwork.

(7c)

(Draw the diagram)

[img]https://i.ibb.co/CK1Fkw4b/Twist-drill.jpg[/img]

===========================

*COMPLETED*

Mr. Femi is an education blogger who simplifies exam updates and study tips for Nigerian students. His goal is to make learning smart, easy, and rewarding.

1 thought on “NABTEB General Metal Work 2025 Questions And Answers”